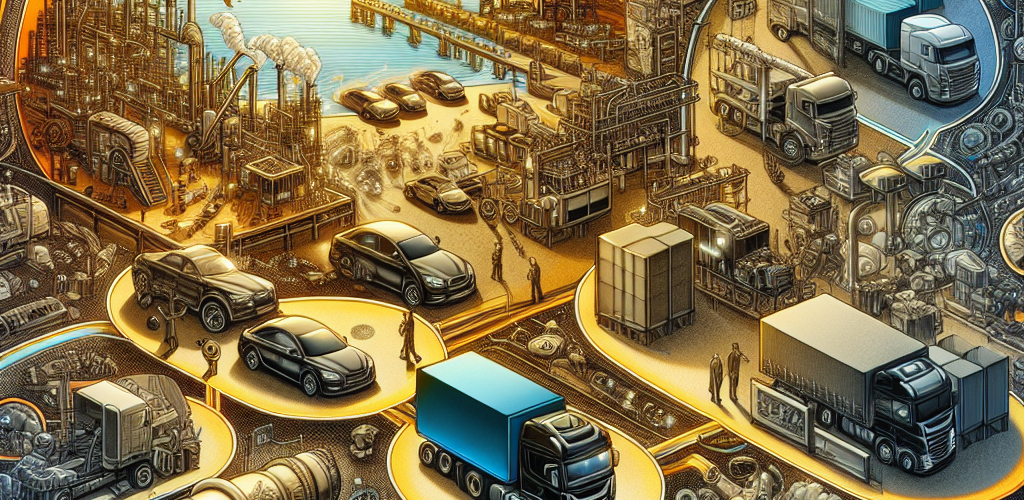

The automotive supply chain is a complex and interconnected network that plays a crucial role in the production and distribution of vehicles worldwide. Recent developments and trends have brought significant changes to this industry, reshaping the way manufacturers and suppliers operate. One of the key global trends impacting the automotive supply chain is the shift towards electric vehicles (EVs). With countries setting ambitious targets to reduce carbon emissions, automakers are ramping up their production of EVs, leading to a surge in demand for components such as batteries and electric drivetrains. This shift is not only changing the type of products being sourced but also the geographical locations of suppliers. As traditional automakers and new entrants invest heavily in EV technology, suppliers in regions like Asia are gaining prominence in the global supply chain. Another important trend shaping the automotive supply chain is the rise of autonomous vehicles. As companies race to develop self-driving technology, there is a growing need for advanced sensors, cameras, and software. This demand is driving collaboration between automakers and tech companies, creating new opportunities and challenges for suppliers. The integration of digital technologies such as artificial intelligence and blockchain is also revolutionizing supply chain management in the automotive industry. These tools are being used to improve visibility, traceability, and efficiency across the supply chain, enabling real-time monitoring of inventory levels, production schedules, and logistics. By leveraging data analytics and automation, manufacturers and suppliers can optimize their operations, reduce costs, and enhance overall performance. However, this digital transformation also brings cybersecurity risks that need to be addressed to ensure the integrity and security of supply chain data. The COVID-19 pandemic has further accelerated the need for resilience and agility in the automotive supply chain. The widespread disruptions caused by the pandemic highlighted the vulnerabilities of relying on single sourcing and just-in-time inventory practices. As a result, companies are reevaluating their supply chain strategies and adopting measures to build more robust and flexible supply networks. This includes diversifying sourcing locations, increasing buffer stock levels, and implementing risk mitigation strategies to better respond to future crises. In conclusion, the automotive supply chain is undergoing a period of rapid transformation driven by technological advancements, changing consumer preferences, and global events. To navigate this evolving landscape successfully, companies must adapt to emerging trends, embrace innovation, and collaborate closely with their partners to build a more resilient and sustainable supply chain.